Can steam be used to decontaminate air conditioning systems without using chemicals?

Yes, steam, thanks to its high temperature (up to 180°C at a pressure of 8 bars) and high pressure, kills harmful micro-organisms. However, unlike disinfection using a combination of steam and a disinfectant product, there is no residual effect over time.

The persistence of a product is the length of time it remains active. It can last up to several days, depending on the products used. This concept is very important in disinfection, as it prevents the environment from being conducive to the proliferation of harmful micro-organisms (bacteria, viruses, spores, fungi, etc.). However, if steam cleaning is carried out regularly, the steam will disinfect the surfaces.

Finally, steam alone needs to be applied to all surfaces very regularly, otherwise the lack of residual effect encourages the development of harmful micro-organisms. However, with steam combined with a disinfectant, distance is irrelevant, which is why it can be used for airborne surface disinfection.

Why dry steam air conditioning cleaning and decontamination?

The use of dry steam at 175°C combined with a pressure of 8 bars makes it possible to :

- Dissolve fats

- Stripping and removing dirt

- Destroying micro-organisms

To ensure that the most resistant strains are destroyed, we use a powerful disinfectant 100 % of biological origin, specific to air conditioners, in conjunction with steam. APABIO - hydrogen peroxide-based disinfectant

APABIO - Ecological disinfectant based on hydrogen peroxide and peracetic acid.

APABIO disinfectant 100% ECOLOGICAL, for air-conditioning decontamination: The total disinfection solution, gentle and non-toxic for people and the environment: 6 points:

- Broad activity: bactericide, fungicide, virucide and sporicide (in accordance with French and European standards):

Bactericide: EN 1040, EN 13727, EN 14561, EN 13697, NFT72-281

Fungicide: EN 1275, EN 13624, EN 14562, EN 13697, NFT72-281

Sporicide: EN 14347, EN 13704, NF T 72-231, NFT72-281

Virucidal: EN 14476.

"Complies with the standard for airborne disinfection: NF T 72-281 (2010) with our equipment (JETBIO 2020 sprayer)

- Stable for 3 years, physical process without additives.

- Biodegradable to MORE THAN 98%

- Food contact

- Non-toxic and non-harmful to humans and the environment

- Contains no formaldehyde, chlorine, phenol or heavy metals

APABIO is a Broad-spectrum organic disinfectant for air-conditioning decontamination.

Highly stable over time.

With a long-lasting, long-lasting effect.

Our process CLIM 3000 will ensure a risk-free operation:

|

|

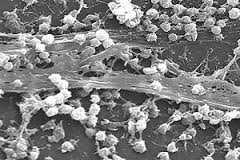

BEFORE - AFTER STEAM CLIM 3000

Why is air conditioning decontamination important?

Air conditioning provides thermal comfort in buildings, but it is also the source of new health, environmental and economic problems. Lack of or poor maintenance of air-conditioning systems can lead to the emergence of numerous illnesses and excessive energy consumption.

Infectious risks :" Air conditioning is certainly comfortable, but it needs to be maintained extremely meticulously and seriously, otherwise the frequency of work stoppages due to Building Syndrome will increase. " (Dr S. Guez - allergique.com/article332.html) Poor air conditioner maintenance encourages the growth of micro-organisms and disperses them in the air. 4 types of pathology have been identified that can have serious pulmonary consequences:

|

Over-consumption of energy :A POORLY MAINTAINED AIR CONDITIONER CONSUMES 30% MORE ENERGY  Air conditioning consumes a lot of energy. On average, 5% of electricity is consumed by air conditioning in a commercial building. Air conditioner manufacturers estimate that 8 grams of dust can lead to energy consumption of 25 to 30% more. Dust also contributes to premature wear and tear on the air conditioner. Regular maintenance of air conditioners helps companies control their energy costs and ensures that the equipment a longer lifespan. |

Air conditioning decontamination is a public health issue!!!!

The technique of deslagging, cleaning and disinfection is perfectly in line with current sustainable development policy. This project has the support of the French National Assembly, which has adopted standards and drafted a bill to require companies to maintain their air conditioning systems.

|